Welcome to the last blog of our series on Industry 4.0. Over the previous four blogs, we have understood what Industry 4.0 really means, how it shall shape tomorrow’s factory, and the challenges companies face in becoming Industry 4.0 compliant.

Welcome to the last blog of our series on Industry 4.0. Over the previous four blogs, we have understood what Industry 4.0 really means, how it shall shape tomorrow’s factory, and the challenges companies face in becoming Industry 4.0 compliant.

Industry 4.0 is a collection of next-gen technologies that helps solve challenges that almost every manufacturing organization faces today – regardless of their offerings or industry. The need to have seamless connectivity across the organization for easier flow of information, access to real-time data, and analysis to get insights. It promises to boost productivity, improve processes, and drive business growth by, essentially, changing the way we approach manufacturing.

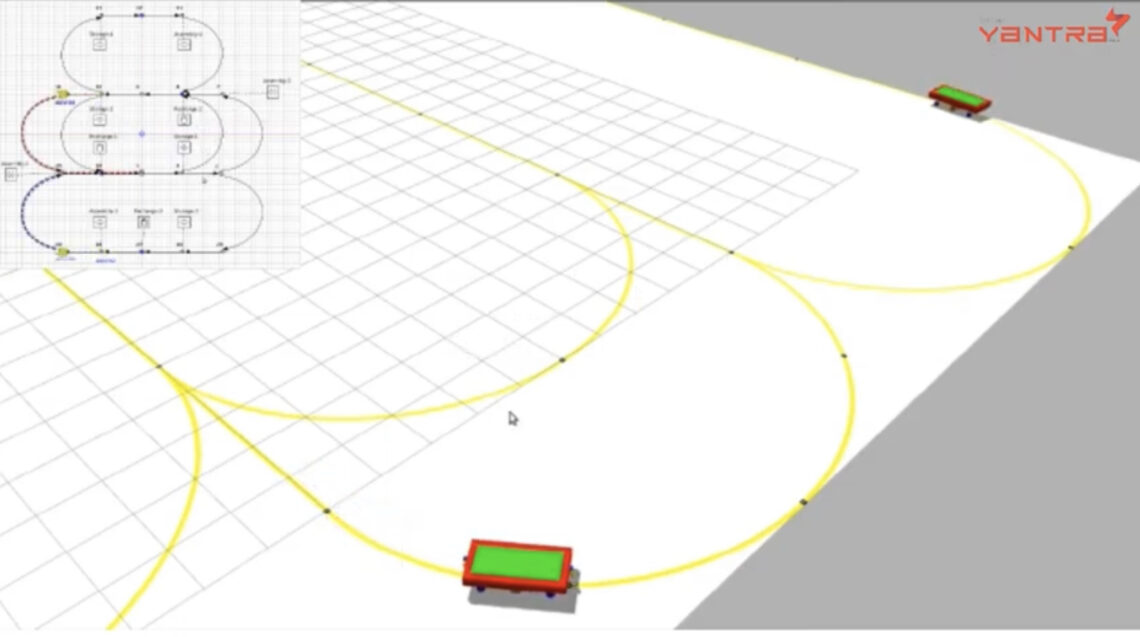

With the background of the previous blogs in mind, we shall take a quick look at how, at Yantra, we are utilizing Industry 4.0 to improve our products and the user experience. Hope you find it interesting.

Remote monitoring and control:

With the advent of the Internet of Things, it has become possible to monitor and control equipment and production remotely through sensors. Likewise, Yantra has also adopted the concept for all its AGVs. Our products are being equipped with an IoT Data Acquisition Device that acquires data directly from the AGV system and relays it to a cloud application. The Yantra and client teams can analyze the data via the cloud and take necessary quick decisions.

Remote monitoring helps the Yantra team to keep a check on AGVs at client sites, identify maintenance issues, and visit immediately to resolve them. It helps avoid regular visits that, often, are not required. Thus, saving a lot of time and cost.

Edge computing for real-time performance monitoring:

Traditionally, measuring any production process or equipment’s performance meant working on historic data utilizing a large amount of human labor for analysis. However, Industry 4.0 promises to transform the traditional approach by enabling real-time data acquisition and analysis.

Edge computing is a concept wherein the processing of data is done closer to the source of data. Instead of relaying the data to the cloud and then analyzing the information, the analysis can be done right on the shop-floor or wherever the data is generated. Thus, edge computing enables quick decisions by making data processing faster.

of data is done closer to the source of data. Instead of relaying the data to the cloud and then analyzing the information, the analysis can be done right on the shop-floor or wherever the data is generated. Thus, edge computing enables quick decisions by making data processing faster.

The IoT framework followed on Yantra AGVs, too, enable edge computing, and therefore, the data from AGVs can be analyzed in real-time on the same location. The production engineers can make use of intuitive dashboards and charts for easy analysis of AGV performance.

‘AGV on OPEX’ model for customers:

Since Yantra AGVs are now equipped with an IoT Data Acquisition Device, it becomes easy to monitor operational parameters such as Operating Time, Idle Time, and Downtime. Real-time data acquisition of these parameters has allowed us to charge our customers as per their usage.

Thus, customers no longer have to pay for the AGVs one-time, upfront. They can pay on a ‘pay-per-use’ model leading to considerable savings in capital expenses. Additionally, we also provide AGVs on rent – through monthly, half-yearly, and yearly rental plans. Remote monitoring of operations, through the adoption of Industry 4.0 in our products, has enabled a more feasible business model for our users.

The adoption of Industry 4.0 technologies is fast increasing across the world. In fact, a white paper from the World Economic Forum, states that 70% of the manufacturers are involved in one or the other Industry 4.0 related activity. As manufacturers realize Industry 4.0 benefits, it shall soon become critical for their vendors and technology providers to imbibe Industry 4.0 aspects in their offerings. Yantra plans to lead the way and provide Industry 4.0 compliant AGV products to our customers.

Stay tuned to our Knowledge Corner as we begin an exciting series of blogs on Artificial Intelligence next.