Deep learning, a subset of artificial intelligence, has emerged as a game-changer across various industries. Deep learning, as we have learned has various pros and cons but when it comes to the Manufacturing Industry, it has a significant role to play. Deep learning is revolutionizing operations by improving efficiency, quality, and safety. In this blog, we will explore the significant role deep learning plays in transforming the manufacturing landscape. Quality Control and Defect Detection Deep learning algorithms have proven highly effective in quality control and defect detection processes in the manufacturing sector. By analyzing large volumes of data and images, deep learning models can identify defects or anomalies that human…

-

-

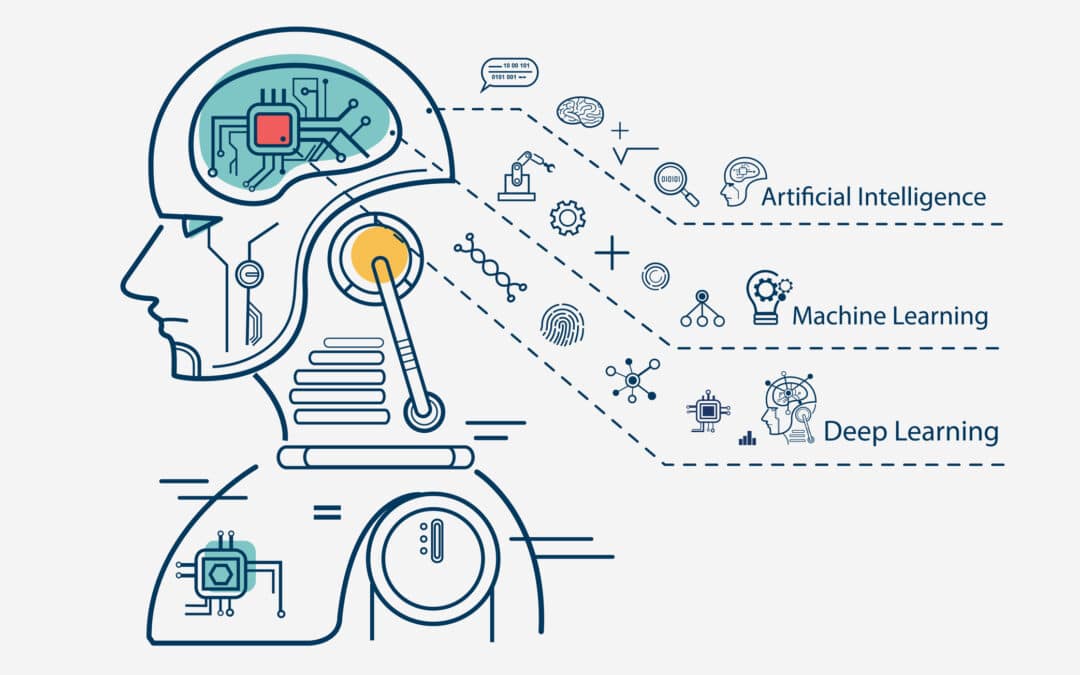

Understanding Deep Learning: Exploring its Advantages and Disadvantages

Deep Learning has revolutionized the field of artificial intelligence, enabling machines to learn and make decisions in once unimaginable ways. However, like any technology, it comes with its own set of advantages and disadvantages. In this blog, we will delve into the fascinating realm of Deep Learning once again, and we will delve into the key benefits and challenges associated with Deep Learning. Advantages of Deep Learning Ability to Learn Complex Patterns: One of the primary advantages of Deep Learning is its exceptional capability to learn and recognize complex patterns. By utilizing multiple layers of neural networks, Deep Learning models can analyze vast amounts of data and automatically extract meaningful…

-

Unlocking the Secrets of Deep Learning for Smarter Decision-Making

“Deep learning is the key to unlocking the full potential of artificial intelligence and ushering in the era of truly intelligent machines.” – Ian Goodfellow, Director of Machine Learning at Apple. Deep Learning, as we learned about in the previous blog, is a powerful subset of artificial intelligence, that has revolutionized various industries with its ability to learn from data and make intelligent decisions. From image recognition to speech synthesis, Deep Learning has found applications in diverse domains. In this blog, we will explore some of the real-life applications of Deep Learning, showcasing its transformative impact on industries worldwide. Computer Vision One of the real-life applications is Computer Vision, enabling…

-

How to Adopt Big Data in the Manufacturing Industry to Attain a Competitive Advantage

“The paradigm of modern manufacturing is not limited to mere production, but rather to production optimization!” This statement by Elon Musk aptly encapsulates the constant pressure on manufacturing companies to innovate, streamline processes, and offer products catered to ever-evolving customer preferences. Integrating Big Data is no longer a matter of choice but a crucial necessity in this milieu. Despite generating an enormous volume of data – spanned across supply chain management, production processes, inventory control, and quality assurance – many manufacturers still face difficulties in harnessing the potential of this data due to inadequate tools and expertise. Streamlining Operations through Big Data Integration Recent studies by Deloitte revealed that only…

-

Big Data, Big Benefits: How It’s Turning Conventional Factories into Data-Driven Mega Factories

“If Big Data is the new crude oil, the manufacturing industry is the furnace!” – This statement holds its weight as active sources continue to generate an explosion of data while companies seek ways to harness this information to gain insights and optimize operations, and drive growth. To dive deeper into this transformative innovation, read our previous blog on Revolutionizing Manufacturing, which comprehensively explores its impact on the manufacturing industry. Now, let’s turn attention to why exactly manufacturers need Big Data. To Employ a Data-Driven Manufacturing, That’s Simple! Imagine a scenario where a manufacturing company is grappling with tons of production data. They have collected this data for years, but…

-

Revolutionizing Manufacturing: How Big Data is Transforming the Industry Today and Tomorrow

“Manufacturing is more than just putting parts together. It’s coming up with ideas, testing principles & perfecting the engineering, as well as the final assembly.” This quote by James Dyson perfectly encapsulates the fast-paced manufacturing industry, where success hinges on one’s ability to harness the latest technological advancements. Big Data is one such technology. Yet, the magnitude of data available can be daunting, leaving many manufacturers needing help to turn it into a strategic advantage. If you have already read our previous blog on Demystifying the Buzz around Big Data: Understanding the Fundamentals & the Underlying 3Vs, you know where we are going: Big Data in Manufacturing: From Assembly to…

-

Demystifying the Buzz around Big Data: Understanding the Fundamentals & the Underlying 3Vs

With every tap and swipe on the internet, you create unstructured bytes of information that inundate businesses daily – even when you clicked on this blog. However, the term Big Data is often tossed loosely as a buzzword by tech enthusiasts. As we recollect the illustrious ‘V’s of Big Data – it becomes apparent that the primary aim of Big Data is to optimize the decision-making mechanism within corporations. Let’s delve into the riveting proliferation of Big Data and its profound significance. Let’s Start with a Comprehensive Definition of Big Data Hear it from the former CEO of an enterprise leading the Big Data innovation at the forefront. IBM’s Ginni…

-

From Traditional to Autonomous: Revolutionizing Warehouses

From a tried-and-true approach to automation, the evolution of warehousing is remarkable. Manual processes, a focus on cost-cutting, and a lack of technological investment characterize the conventional model. While this model has served businesses well in the past, it’s considerably slow, labor-intensive, and more prone to human error. As the demands of commerce grew, so did the need for an agile, efficient, and adaptable warehouse solution – making it pivotal for CXOs to learn the potential impact of modern technologies on business operations and how they are shaping the future of commerce. Enter the rise of automation. With the help of technology, warehouses can streamline their operations, reduce the risk…

-

Navigating Through the Challenges of Robotics in Warehouse Automation

When we imagine automation, we picture a futuristic warehouse operation where robots are assigned with all the heavy lifting. However, that is far from reality. Industrial automation has been synonymous with the logistics industry for decades. With an increasing demand for faster, more efficient, and cost-effective supply chains, the use of robotics in warehouses has been rising. Continuing our previous blog, “Guide To Different Types Of Automation Robots”, we’ll talk about the challenges prohibiting companies from adopting warehouse automation at a large scale. First, let’s look at the market trends in warehouse automation. According to a recent report by MarketsandMarkets, the global market for robotics and automation in warehouses is…

-

Overcoming the challenges of automation in manufacturing

In the last three blogs, we have tried to understand automation in manufacturing and warehousing as well as its types and benefits. But, just as every coin has two sides, automation poses certain challenges. Let’s talk about those now. It is predicted that 20 million jobs will be displaced due to automation in manufacturing by 2030. This figure suggests that around 46% of jobs will be lost by 2030. Each year there is a staggering 10% increase in automation. Lately, automation in the manufacturing sector has picked up as it reduces labor costs, increases production speed, and improves accuracy. But specific challenges still pose a threat to its guilt-free and full-scale adoption. What are the challenges…