Welcome to the last blog of our series on Industry 4.0. Over the previous four blogs, we have understood what Industry 4.0 really means, how it shall shape tomorrow’s factory, and the challenges companies face in becoming Industry 4.0 compliant. Industry 4.0 is a collection of next-gen technologies that helps solve challenges that almost every manufacturing organization faces today – regardless of their offerings or industry. The need to have seamless connectivity across the organization for easier flow of information, access to real-time data, and analysis to get insights. It promises to boost productivity, improve processes, and drive business growth by, essentially, changing the way we approach manufacturing. With the…

-

-

Adopting Industry 4.0 – The Challenges

Through the blog series on Industry 4.0, we have taken a close look at what Industry 4.0 is, how it promises to transform manufacturing, and how it shall impact warehousing. Before we conclude this fascinating series, we shall look at the major challenges manufacturers face in their pursuit of Industry 4.0. We have made sure that we provide a few tips to work around the challenges. Hope you find…

-

A look at the factory of tomorrow

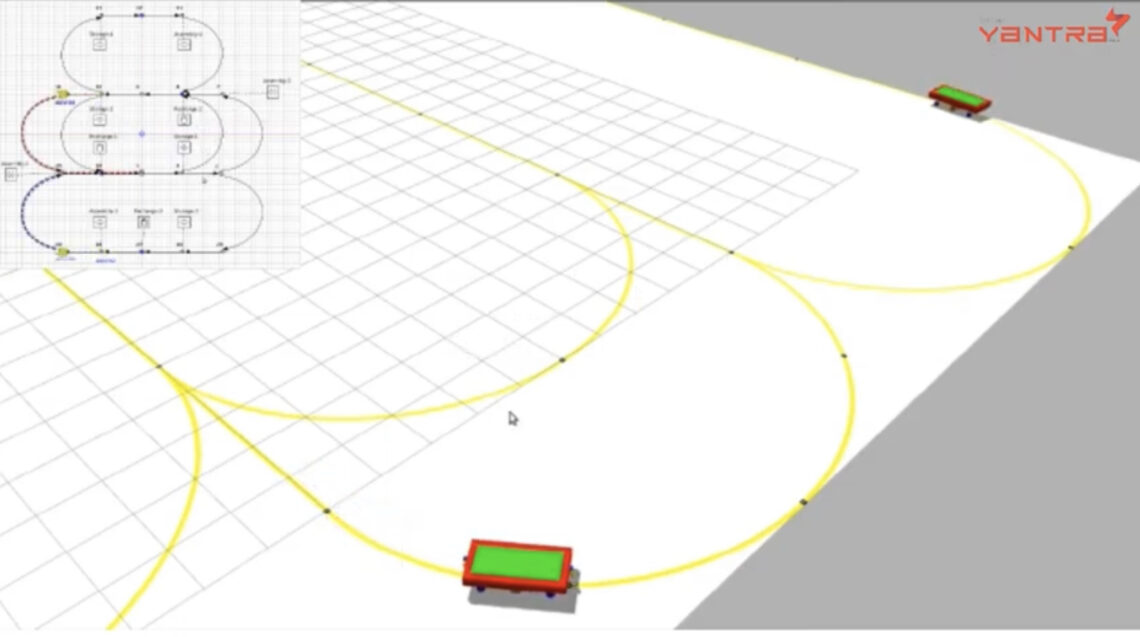

Industry 4.0, as we saw in the previous blog, is a radically different approach to manufacturing. It makes use of a collection of next-gen technologies to solve the problems that business owners face today. It enables collaboration across the organization, provides access to real-time data, and can derive insights from a vast amount of data for process optimization. In the first (Industry 4.0 an Overview) of a series of blogs on Industry 4.0, we took a glimpse into what Industry 4.0 means and the underlying technologies that make it up. Here, we shall try and imagine how an Industry 4.0-enabled company shall manufacture its products. Let us look at five…

-

Industry 4.0 – An Overview

Over the last couple of centuries, manufacturing has undergone many changes courtesy of three industrial revolutions. The first industrial revolution witnessed the rise of mechanization through the use of water and steam power. The second brought about mass production and assembly lines using electricity. Finally, the third industrial revolution enabled computers to automate specific processes and increase their efficiency. However, one more industrial revolution has come to the fore in the past few decades – Industry 4.0. It aims to use ‘digital’ to a whole new level; interconnectivity between manufacturing departments and processes, access to real-time data, and the birth of cyber-physical systems are the notable promises of Industry 4.0.…