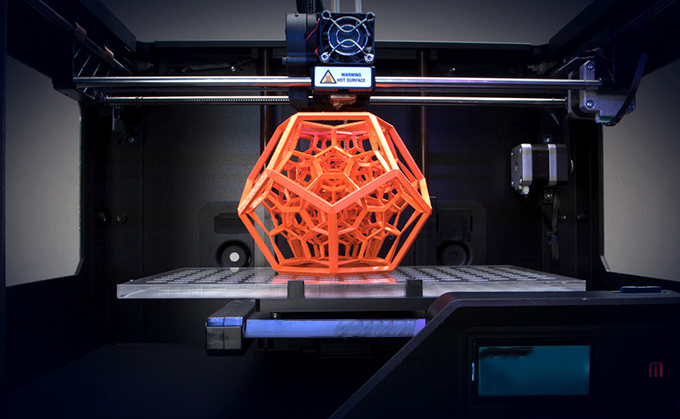

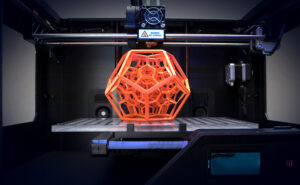

As discussed in the previous blogs, it can be considered that as far as the latest innovations go, 3D printing can be regarded as one of the most promising technologies of recent times. The additive manufacturing process creates an opportunity to manufacture products in a more unique and controlled way than traditional methods.

As discussed in the previous blogs, it can be considered that as far as the latest innovations go, 3D printing can be regarded as one of the most promising technologies of recent times. The additive manufacturing process creates an opportunity to manufacture products in a more unique and controlled way than traditional methods.

There are many different types of 3D printing technologies, but the advantages of 3D printing discussed below apply to the whole industry.

Rapid Prototyping

One of the most significant outcomes of 3D printing is Rapid Prototyping. Rapid prototyping is the capacity to plan, fabricate, and test a product prototype as quickly as possible.

Before the 3D printing industry came to thrive, a prototype would take weeks to fabricate. Each time a revision was required, another few weeks would be added to the method. Overall, a product would take months, if not years, to finalize.

With 3D printing strategies, the same product development cycle can be brought down to weeks, and days, in some cases. This leads to quicker rollout, lower development costs, and ease of decision-making.

Affordable

Traditionally, expensive CNC machines or other manufacturing setups are required for small production runs or manufacturing complex parts. Moreover, trained labor is needed to operate such machines at a high cost.

Contrast that with 3D printing technology, where a single relatively inexpensive machine can manufacture the most complex parts quickly and without the need of costly labor as manual intervention is minimal.

Single-step manufacture and greater control

Conventional manufacturing requires different sub-parts to be manufactured separately and then assembled to deliver the final design. The downfall, in this case, is the vast number of processes that are necessary for different sub-parts, the need to assemble them all, and the logistics and planning needed to manufacture the items efficiently.

to be manufactured separately and then assembled to deliver the final design. The downfall, in this case, is the vast number of processes that are necessary for different sub-parts, the need to assemble them all, and the logistics and planning needed to manufacture the items efficiently.

On the other hand, 3D printing is a single-step manufacturing process, i.e., once the final design is ready in CAD format, the 3D printer can manufacture the product in one go. Thus, manufacturing can become faster and save a lot of costs.

Customization

As 3D printing allows extraordinary design freedom, individual products can be custom-made to suit a particular scenario or person. Primarily, it has been embraced by the medical fraternity to develop custom prosthetics, inserts, and dental help. Even high-end sporting equipment is custom-made to fit a sports person allowing them to perform better. Such customization would otherwise incur high costs.

Sustainability

Lesser processes lead to fewer factories and a lesser need for transporting material. All in all, this leads to a lesser carbon footprint. Moreover, material that goes as waste after manufacturing a product can also be recycled.

3D printing is, thus, more sustainable and environment-friendly.

Conclusion

3D technology has many advantages from which the manufacturing industry can benefit. This technology is already being used and will get refined going ahead. It is just a matter of time before most businesses realize the benefits and shift manufacturing methods.

We shall keep you updated about 3D Printing developments. Stay tuned to our Knowledge Corner.