Welcome to the last blog of our series on Industry 4.0. Over the previous four blogs, we have understood what Industry 4.0 really means, how it shall shape tomorrow’s factory, and the challenges companies face in becoming Industry 4.0 compliant. Industry 4.0 is a collection of next-gen technologies that helps solve challenges that almost every manufacturing organization faces today – regardless of their offerings or industry. The need to have seamless connectivity across the organization for easier flow of information, access to real-time data, and analysis to get insights. It promises to boost productivity, improve processes, and drive business growth by, essentially, changing the way we approach manufacturing. With the…

-

-

Adopting Industry 4.0 – The Challenges

Through the blog series on Industry 4.0, we have taken a close look at what Industry 4.0 is, how it promises to transform manufacturing, and how it shall impact warehousing. Before we conclude this fascinating series, we shall look at the major challenges manufacturers face in their pursuit of Industry 4.0. We have made sure that we provide a few tips to work around the challenges. Hope you find…

-

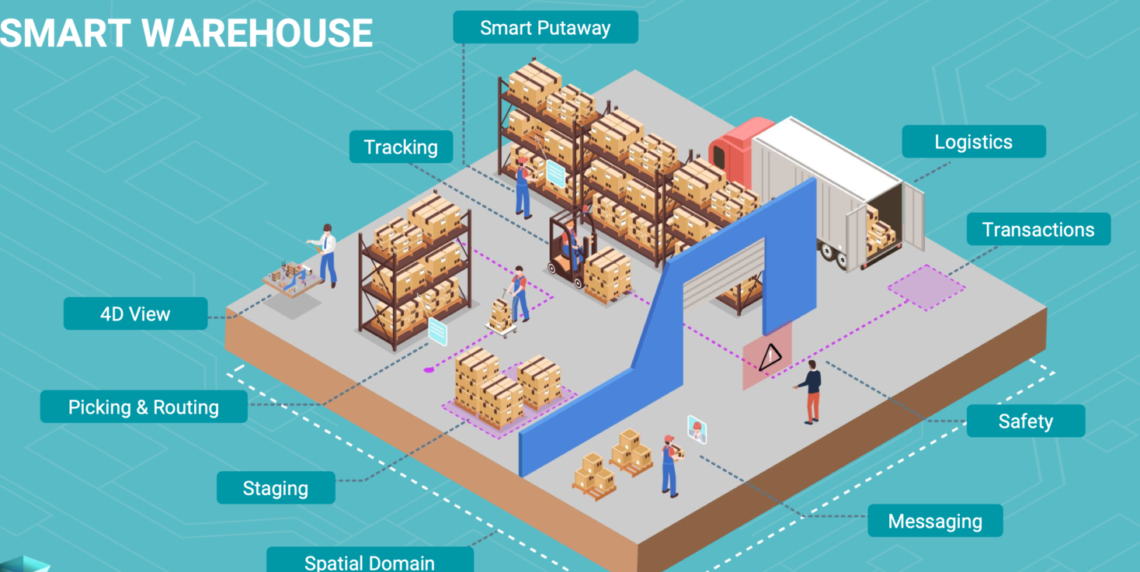

How will Industry 4.0 impact warehousing?

As we have seen in our previous blogs, the fourth industrial revolution promises to transform the entire manufacturing spectrum in the coming years entirely. However, manufacturing is not alone. Industry 4.0 shall have a transformational impact on supply chain management as well, especially warehousing operations. In this blog, we shall look at five ways Industry 4.0 shall affect warehousing operations for the better. Hope you find it interesting! Warehousing: The Challenges Faced Today Although automated warehouses have been around for a while, the adoption rate of next-gen technologies in the warehousing industry has been relatively lower. And thus, the challenges that warehouse operators have faced remained, more or less, the…

-

A look at the factory of tomorrow

Industry 4.0, as we saw in the previous blog, is a radically different approach to manufacturing. It makes use of a collection of next-gen technologies to solve the problems that business owners face today. It enables collaboration across the organization, provides access to real-time data, and can derive insights from a vast amount of data for process optimization. In the first (Industry 4.0 an Overview) of a series of blogs on Industry 4.0, we took a glimpse into what Industry 4.0 means and the underlying technologies that make it up. Here, we shall try and imagine how an Industry 4.0-enabled company shall manufacture its products. Let us look at five…

-

Industry 4.0 – An Overview

Over the last couple of centuries, manufacturing has undergone many changes courtesy of three industrial revolutions. The first industrial revolution witnessed the rise of mechanization through the use of water and steam power. The second brought about mass production and assembly lines using electricity. Finally, the third industrial revolution enabled computers to automate specific processes and increase their efficiency. However, one more industrial revolution has come to the fore in the past few decades – Industry 4.0. It aims to use ‘digital’ to a whole new level; interconnectivity between manufacturing departments and processes, access to real-time data, and the birth of cyber-physical systems are the notable promises of Industry 4.0.…

-

IoT and the Transformation of Material Handling

As we continue the series of focused blogs on next-gen technologies, we shall now look at how the Internet of Things promises to transform material handling forever. Any improvement in material handling, which plays a pivotal part in any industry’s supply chain, translates into meaningful business value. Manufacturers and warehouse owners continuously try to speed up processes, increase worker efficiency, avoid product damage, and ensure overall safety. With the embrace of IoT, industry players can hope to improve on all these aspects. Let us see how! Increased visibility For years, sensors and tags – RFID and barcode – have been used to track materials and products through the warehouse. Real-time…

-

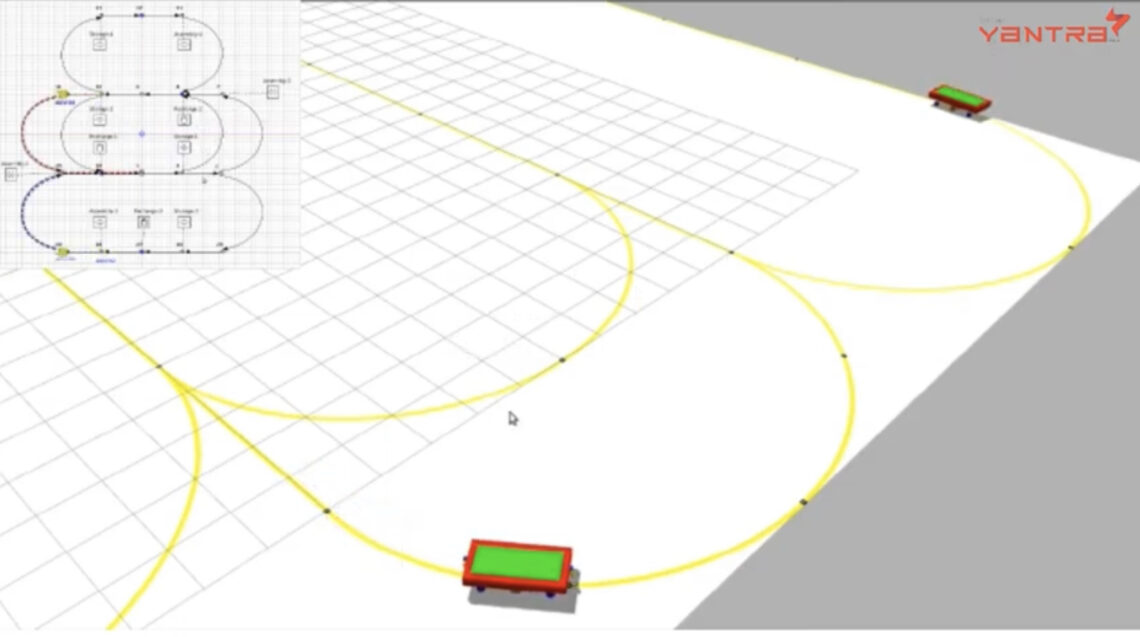

IoT and The World of Autonomous Material Handling

In the last blog, we glimpsed into how the Internet of Things revolutionizes businesses and, ultimately, our lives. Connecting every possible physical object on the shop-floor to the internet via sensors leads to the generation of a massive amount of insightful data. Data that can be used to make processes more efficient, reduce costs and, increase output. IoT brings together data-acquiring sensors, internet, cloud computing, and analytics capabilities to deliver real-time information to business leaders to make effective smart decisions. We ask, what if the power of IoT can be used to improve the design and usage of autonomous material handling equipment like AGVs and AMRs? Read on to see…

-

Internet of Things: An Overview

Today, we hear about several new technologies and their impact on our personal lives and businesses. Internet of Things, Artificial Intelligence, Machine Learning, etc. have become ‘talk-of-the-town’ and are spoken of by laymen, business leaders, and governments equally highly. We, Yantra, are a tech-driven company and, thus, plan to throw some light on some of the next-gen technologies in the form of a series of focused blogs. We hope you all find it valuable. The following piece aims to introduce the Internet of Things and get a glimpse into how it may affect people and businesses. Read on! IoT: Connecting Anything and Everything Quite simply, IoT is about connecting anything…