Some of the technologies that have had an astronomical impact on society are the light bulb, steam engine, cars, mobile phones, the internet, etc. But, some say that 3D Printing has a more significant potential than even the internet!! Is that possible?

Some of the technologies that have had an astronomical impact on society are the light bulb, steam engine, cars, mobile phones, the internet, etc. But, some say that 3D Printing has a more significant potential than even the internet!! Is that possible?

Through the following series of blogs, we will look deeply at 3D Printing. We shall understand what it entails, its effect on our lifestyle and business, and its impact on manufacturing. We wish to explore why there is so much talk around this new-age technology. So let’s dive right in!

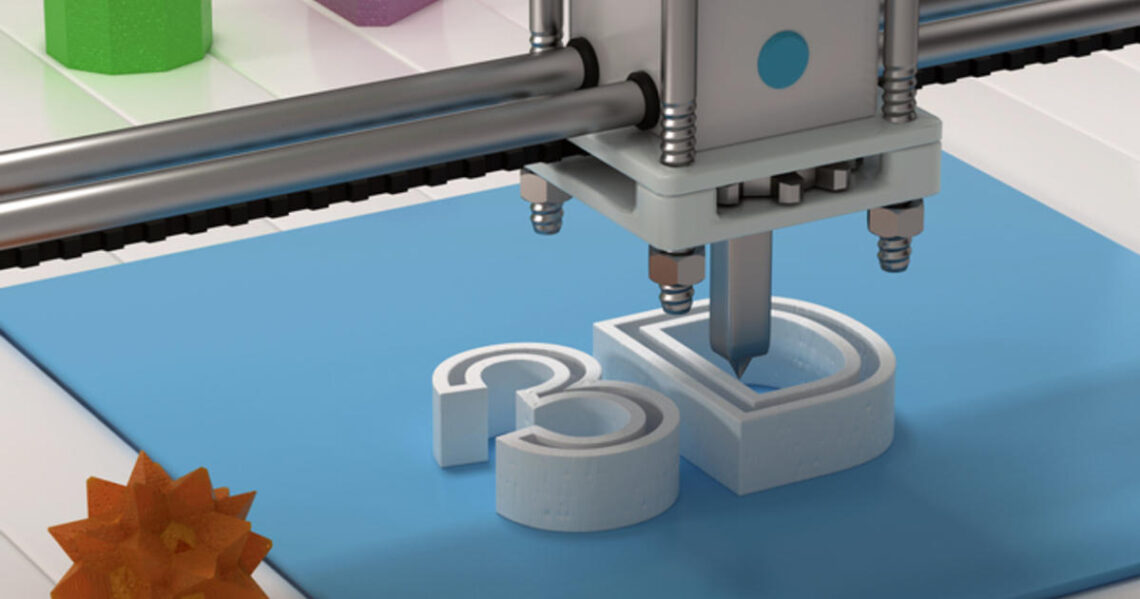

What is 3D Printing?

In very casual language, it’s like building something with Lego blocks automatically. On a more serious note, 3D Printing refers to turning 3-dimensional digital models into physical objects through a layer-by-layer addition of material. It’s also called additive manufacturing for the same reason – an object is created by adding thin successive layers. The additive nature of manufacturing makes 3D Printing radically different from any existing manufacturing process.

Vis-à-vis Traditional Manufacturing

Traditional manufacturing relies on the concept of subtracting material from a larger block to form desired objects, irrespective of whether the processes are performed by human labor or using automated machinery. Subtractive processes pose a lot of constraints, such as the expensive tools required, the need for assembly of complex parts, and the massive amount of wastage generated after processing the original block of material. A subtractive process can cause about 90% wastage in the material.

The other end of the spectrum is 3D Printing. When it’s about adding successive layers, there is minimal wastage of material, if any. Thus, it is a far more environmentally-friendly process. Objects can be made without assembly; intricate and complex designs can be directly formed using a 3D Printer. Thus, it reduces costs and lead times.

Another advantage of 3D Printing is the design freedom the manufacturer gets as well as the freedom to choose from a range of materials to form the object, unlike traditional processes.

Real-world examples

Exciting and unique applications are coming up in various parts of the world. And there is no limit to the material being used, designs being imagined, and the sizes of objects.

up in various parts of the world. And there is no limit to the material being used, designs being imagined, and the sizes of objects.

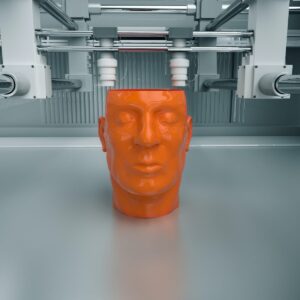

For example, in India, some doctors began 3D Printing models of various human body parts, like kidneys, to practice on before operating on the actual patient. Such prototypes will be a great help for teaching and shall contribute to saving lives in the future.

A completely different example comes from Spain, where a restaurant uses a 3D Printer to design complex food structures made from potatoes and chocolate. Who wouldn’t love those?!

Some of the other industries and applications deploying 3D Printing are as follows:

- Consumer and fashion products such as eyewear, footwear, design, and furniture

- Industrial products and manufacturing tools such as prototypes and functional end-use parts

- Dental and medical products

- Architectural scale models

- Reconstructing fossils

- Replicating ancient artifacts

- Reconstructing evidence in forensic pathology

- Movie props

Conclusion

Thus, almost every industry has already been touched by 3D Printing. It is helping industries to deliver quick and cost-friendly products.

3D Printing has immense potential and is already shaking up our notions about what can be built and what cannot. It can drive great innovation and faster and cheaper services for industries. The growth of 3D Printing is certainly a trend to be looked forward to, and we’ll make sure to do that. Keep yourself updated with Rucha Yantra’s regular blog series. Stay tuned to our Knowledge Corner.