From a tried-and-true approach to automation, the evolution of warehousing is remarkable. Manual processes, a focus on cost-cutting, and a lack of technological investment characterize the conventional model. While this model has served businesses well in the past, it’s considerably slow, labor-intensive, and more prone to human error. As the demands of commerce grew, so did the need for an agile, efficient, and adaptable warehouse solution – making it pivotal for CXOs to learn the potential impact of modern technologies on business operations and how they are shaping the future of commerce. Enter the rise of automation. With the help of technology, warehouses can streamline their operations, reduce the risk…

-

-

5 Types of Robots Transforming the Warehouse

You’d be amazed to know how much revenue the global warehouse automation market generated in 2021! As per Statista, the numbers stand at $7.91 billion, with an estimated $51 billion by 2030. The traction was mainly due to the boost in automation efforts to tackle the workforce shortage during the pandemic. Even with the pandemic subsiding, though, we can see that the market for Robotics for warehouse management is increasing rapidly. Welcome back to the 2nd blog in the series. This time, we’ll look at the different types of robots transforming the warehouse. Let’s start! Automated Guided Vehicles (AGVs) Automated Guided Vehicles are self-driving cars that navigate through the warehouse…

-

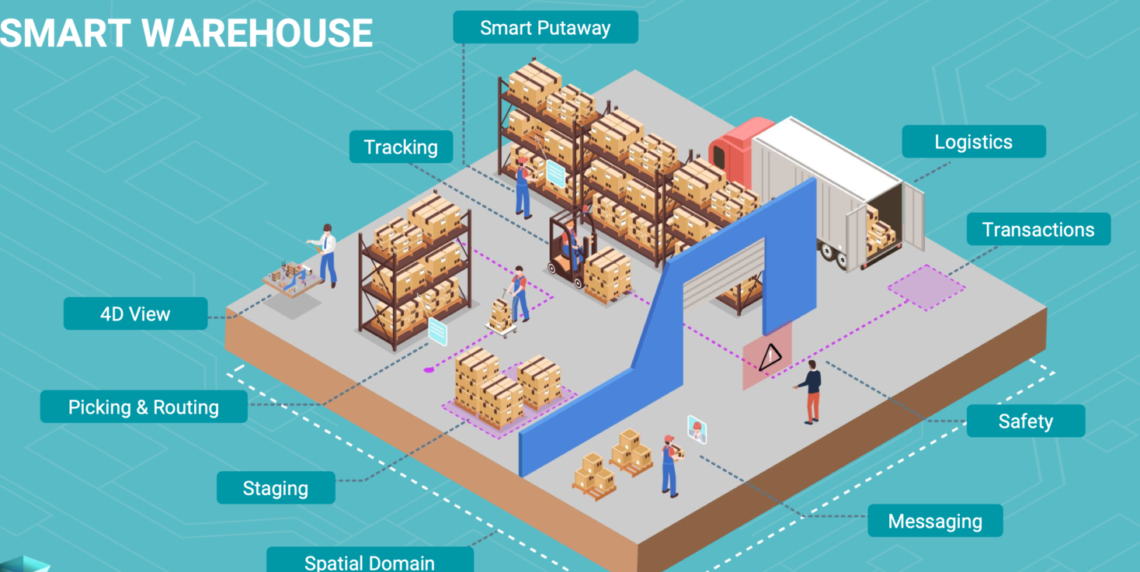

A Brief on Warehouse Automation

Continuing our series on automation, we have now brought up the topic of Warehouse Automation. Warehouse automation is a significant contributor to the growth and economy of a country. There are approximately 167,610 warehouses worldwide, with more than 80% lacking automation. The warehouse automation industry is going to boom under Industry 4.0. Robotics, logistics, and other warehouse automation technologies are anticipated to reach a global value of over $22.4 billion. The need for warehouse automation is immense as the majority of operating budgets for warehouse facilities are composed of roughly 65% labor costs! Warehouse automation also brings safety to the environment. The number of forklift-related accidents alone totals nearly 100,000…

-

The many benefits of warehouse robotics

Welcome back! As we wrap up the series on warehouse robotics, where we understand the term and the different types of warehouse robots in the previous two blogs, today, we shall list down the many benefits of putting robots to use in warehouses. Let’s begin. Industrial productivity has come a long way since the 18th century. Not only have industries revamped themselves in terms of the total output, but the resources expended to produce a single unit of any finished product have also dramatically come down. Novel technological innovations have helped companies achieve both of these objectives simultaneously. Robotics is one such technology. Unerring accuracy, uninterrupted efficiency, and top-notch productivity…

-

The 7 Types of Robots that are Rewriting Norms of Industrial Productivity

Welcome back. In the last piece, we looked at how warehouse robotics has evolved into a mainstream application subject, its benefits, and the various use cases. This time around, we shall look at the different types of robots out there classified basis applications. Let’s begin! Over the years, robotics as an aspect of industrial science has evolved in leaps and bounds to be able to substitute many of the factory/warehouse floor activities that require human intervention. Today, activities like picking, segregating, packing and transportation are handled by robots in most technologically advanced companies. Without further ado, let us dig into the different kinds of robots at work on the factory…

-

How robotics is re-engineering the warehousing dynamics

The manufacturing world is no stranger to technological transformations. Robotics is one such transition that has been in the works for decades and is coming into its own. It is yielding higher revenue and drastically reducing costs for firms globally. Warehouse robotics essentially involves using state-of-the-art automated systems, robotic machines, and software for executing routine, run-of-the-mill tasks in the warehouse. Once looked at with much skepticism, these robotic elements have risen to a position where companies insist on them being an inextricable part of the supply chain. The larger question that many Indian companies remain unconvinced about is the possible benefit that will accrue to their bottom line by using…

-

How will Industry 4.0 impact warehousing?

As we have seen in our previous blogs, the fourth industrial revolution promises to transform the entire manufacturing spectrum in the coming years entirely. However, manufacturing is not alone. Industry 4.0 shall have a transformational impact on supply chain management as well, especially warehousing operations. In this blog, we shall look at five ways Industry 4.0 shall affect warehousing operations for the better. Hope you find it interesting! Warehousing: The Challenges Faced Today Although automated warehouses have been around for a while, the adoption rate of next-gen technologies in the warehousing industry has been relatively lower. And thus, the challenges that warehouse operators have faced remained, more or less, the…

-

Mobile Robots for Warehousing

Warehousing is the age-old process of storing goods safely after they are brought from manufacturer and before shipping them off to the distributor or customer. Though the definition remains the same, the process has undergone a considerable change over the years. With the increasing diversification of logistics and enterprise models, warehousing has also been modernized to a great extent. During this unprecedented COVID-19 situation, world economy has definitely seen a rise in e-commerce sales and trade, leading to increase in the demand for optimum warehousing solutions specially for e-commerce giants like #Amazon and #Flipkart. The latest trend in this is Warehousing Robots. At Rucha Yatra LLP we focus on building commercial…

-

AGVs in Textile

Material Handling in manufacturing sector refers to the movement of any kind of material/load within the limits of shop floor or at the most to the transportation vehicles or warehouses. Auto Guided Vehicles (AGVs) are the newest trend in material handling. AGVs are portable robots, which follow a prefixed path for navigation. They can tow the material stored on trailers and trolleys attached behind them or can store the material on the overhead beds for conveyance. They are used to transport loads in a manufacturing facility or a warehouse, where repetitive movement of material is required with little or no human interaction. Now a days, they are deployed in nearly every…