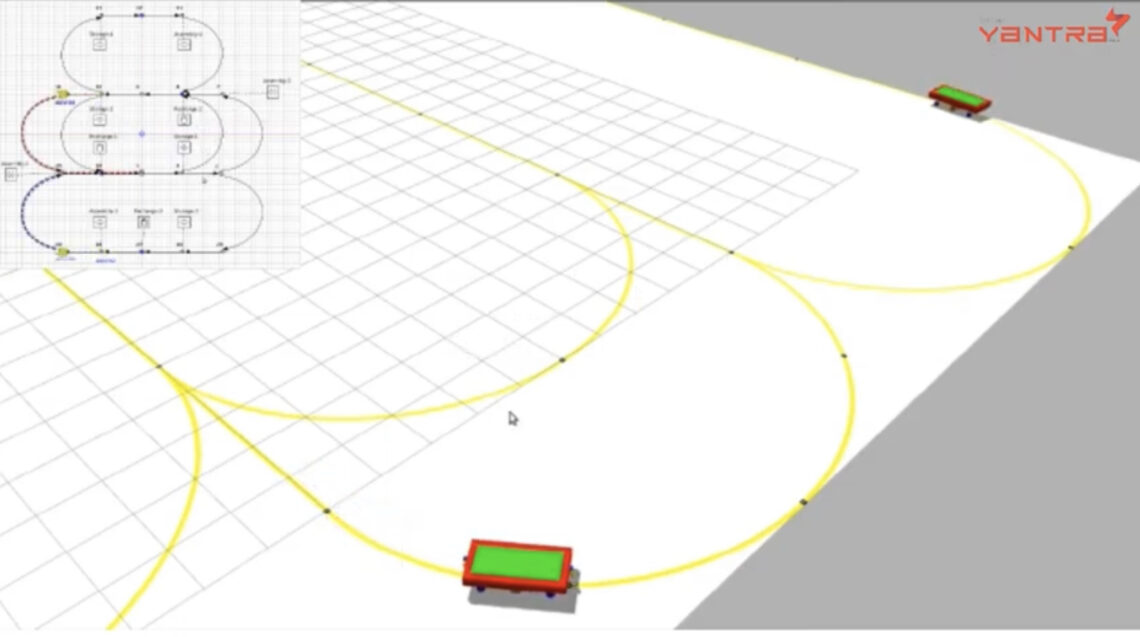

You’d be amazed to know how much revenue the global warehouse automation market generated in 2021! As per Statista, the numbers stand at $7.91 billion, with an estimated $51 billion by 2030. The traction was mainly due to the boost in automation efforts to tackle the workforce shortage during the pandemic. Even with the pandemic subsiding, though, we can see that the market for Robotics for warehouse management is increasing rapidly. Welcome back to the 2nd blog in the series. This time, we’ll look at the different types of robots transforming the warehouse. Let’s start! Automated Guided Vehicles (AGVs) Automated Guided Vehicles are self-driving cars that navigate through the warehouse…

-

-

Impact and Rise of Service Robots in Healthcare

Before we conclude the blog series on Robotics in Healthcare, we shall look at an essential type of robot taking the healthcare world by storm. Service robots relieve the burden on healthcare workers and paramedical staff by taking up routine logistical tasks. These robots can set up patient rooms, track supplies and file purchase orders, restock medical supply cabinets, and transport bed linens to and from laundry facilities. Delegating such tasks to robots helps the staff have more time for jobs that require human interaction and judgment. The rise of service robots The covid-19 pandemic has changed the way we live and work with each other. Sanitation requirements and social…

-

Robotics in Healthcare: Applications (Part 1)

The series starting with this blog was chosen by you – our readers and followers. Thus, we are extra excited about sharing interesting information through the upcoming blogs. We shall be talking about the confluence of 2 industries that are heavily trending at the moment. Robotics and healthcare! Hope you find the series engaging. The stress on greater precision in surgeries, better management of patients and hospitals, and reducing human errors in treatment keeps pushing the healthcare industry to adopt newer technologies. One such technology is robotics. The use of robotics in healthcare can be traced back to the 1980s when used for precise positioning of the cannula for brain…

-

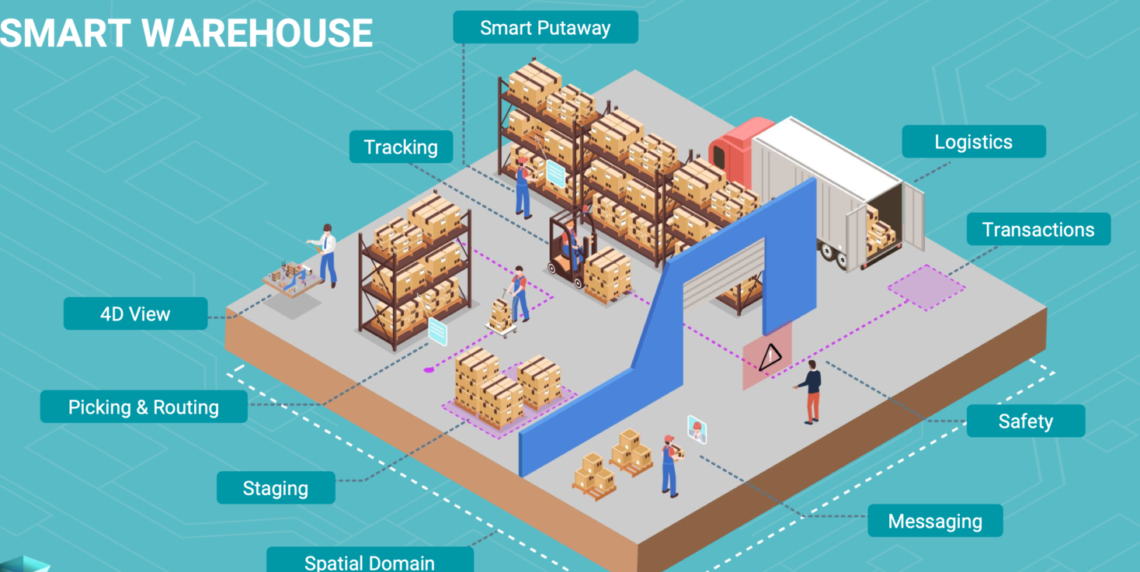

5 Reasons Why Your Warehouse Needs Machine Learning

Welcome back as we conclude the Machine Learning (ML) series with this last interesting piece. We began the series by understanding what ML means. Then we looked at the different technical approaches that can be taken under ML. In the last blog, we focused on the impact of ML on manufacturing. We have tried to bring ML in more simplistic terms to our friends from manufacturing. And thus, we shall conclude the series with a piece on how you can use ML to enhance warehouses – a crucial component of the manufacturing cycle. Advancements in technology are not new to warehouses, and ML is just the latest type on the…

-

Artificial Intelligence – An Overview

Welcome to a new blog series on one of the most exciting and talk-about technologies globally – Artificial Intelligence (AI). We took a deep dive into what Industry 4.0 entails in our previous series, and now, we shall take a closer look at all the underlying technologies one by one, starting with AI. Read on to know what AI stands for, its various applications in the industry, and the three major types of AI. What does Artificial Intelligence stand for? It is, essentially, a vast branch of computer science that concerns building smart machines that can perform tasks that typically need human intelligence. The primary purpose of AI is…

-

How Industry 4.0 is integral to Yantra’s products

Welcome to the last blog of our series on Industry 4.0. Over the previous four blogs, we have understood what Industry 4.0 really means, how it shall shape tomorrow’s factory, and the challenges companies face in becoming Industry 4.0 compliant. Industry 4.0 is a collection of next-gen technologies that helps solve challenges that almost every manufacturing organization faces today – regardless of their offerings or industry. The need to have seamless connectivity across the organization for easier flow of information, access to real-time data, and analysis to get insights. It promises to boost productivity, improve processes, and drive business growth by, essentially, changing the way we approach manufacturing. With the…

-

Adopting Industry 4.0 – The Challenges

Through the blog series on Industry 4.0, we have taken a close look at what Industry 4.0 is, how it promises to transform manufacturing, and how it shall impact warehousing. Before we conclude this fascinating series, we shall look at the major challenges manufacturers face in their pursuit of Industry 4.0. We have made sure that we provide a few tips to work around the challenges. Hope you find…

-

How will Industry 4.0 impact warehousing?

As we have seen in our previous blogs, the fourth industrial revolution promises to transform the entire manufacturing spectrum in the coming years entirely. However, manufacturing is not alone. Industry 4.0 shall have a transformational impact on supply chain management as well, especially warehousing operations. In this blog, we shall look at five ways Industry 4.0 shall affect warehousing operations for the better. Hope you find it interesting! Warehousing: The Challenges Faced Today Although automated warehouses have been around for a while, the adoption rate of next-gen technologies in the warehousing industry has been relatively lower. And thus, the challenges that warehouse operators have faced remained, more or less, the…

-

IoT and the Transformation of Material Handling

As we continue the series of focused blogs on next-gen technologies, we shall now look at how the Internet of Things promises to transform material handling forever. Any improvement in material handling, which plays a pivotal part in any industry’s supply chain, translates into meaningful business value. Manufacturers and warehouse owners continuously try to speed up processes, increase worker efficiency, avoid product damage, and ensure overall safety. With the embrace of IoT, industry players can hope to improve on all these aspects. Let us see how! Increased visibility For years, sensors and tags – RFID and barcode – have been used to track materials and products through the warehouse. Real-time…

-

IoT and The World of Autonomous Material Handling

In the last blog, we glimpsed into how the Internet of Things revolutionizes businesses and, ultimately, our lives. Connecting every possible physical object on the shop-floor to the internet via sensors leads to the generation of a massive amount of insightful data. Data that can be used to make processes more efficient, reduce costs and, increase output. IoT brings together data-acquiring sensors, internet, cloud computing, and analytics capabilities to deliver real-time information to business leaders to make effective smart decisions. We ask, what if the power of IoT can be used to improve the design and usage of autonomous material handling equipment like AGVs and AMRs? Read on to see…